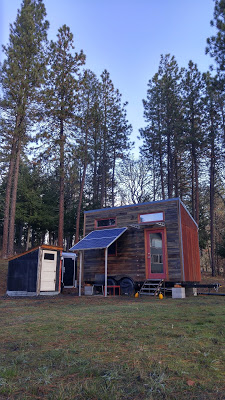

This past weekend, I helped move two new tiny homes into the yard where I had been living for the past two years. Both homes were being built at Green Anchors (my build site as well) but the builders were ready to relocate into their future living spots. They hired a towing company and early Saturday morning (7:30am!) the first house arrived.

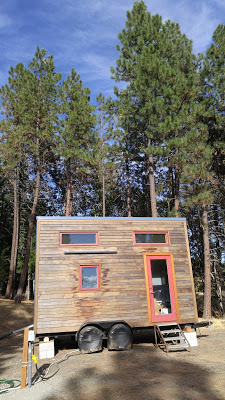

Since this house was going to be located at the front of the yard next to the fence, the plan was to drive in forward and then back the house into the prepared spot. Driving in want fairly well though we needed to add some blocks under the tires due to the steep driveway (but hey, at least it is graveled now!) The driver also avoided trampling most of the garden which meant a little less space to work in. Luckily he had a towing receiver that could adjust the tongue left to right, up, down, forward and backward.

We also ended up using the borrowed power mover to help steer it into place. We operated it on top of scraps of plywood to keep the wheels from spinning in the soft ground. It was really great to have seven people be a part of this move process especially as we had to keep shifting the plywood scraps in front of the power mover's path and keep an eye out to avoid any collisions.

With the first house in place, the truck driver was off to grab the second one and we spent the time doing a little site work to re-level out the ground. We also took a break to eat bagels with various spreads including nutella!

Before we knew it, the truck driver was back with the second house in tow. This one he backed into the yard and it was fun to see the two homes side by side for a minute!

We had to complete the move with the power mover due to yard obstacles but that went smoothly due to the plywood. I still think we need a version with spikes for soft ground though!

By early afternoon, the yard had transformed to a little tiny house community (or future community since they are all still under construction). It will be neat to see the progression of that space over time.