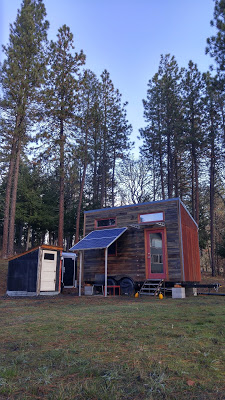

Before I moved my home this summer, I disconnected my solar panels and disassembled the wooden support structure in order to transport them unattached to my home. Once settled into my new site, the plan was to build a new support structure with aluminum so that the awning could fold down and be structurally safe while attached during transport.

The design for the new frame is similar to the old one, trading 2x2 cedar supports for 1 1/2" x 1 1/2" and 1 1/2" x 2 1/2" aluminum C channel. I drilled holes in the bottom of each section of channel to align with the holes in the solar panel frames. In more typical residential solar installs, special rails and hardware clamp the panels in place but I was looking for a lower profile design since I had just under 2" depth to play with. I placed the narrower channels in the middle and wider ones on the outside since they would also accommodate the vertical support posts.

With all of the holes drilled, I went to work attaching them with bolts, nuts, washers and lock washers to the piece of 2" unistrut tube that was already attached to my house via welded on hinges, a piece of angle iron and all-thread. Of course I had to measure to make sure their placement would line up with the spacing of the holes in the solar panel frames. I also didn't tighten things down completely since it's a good idea to wait until everything is in place just in case a little extra wiggle room is necessary.

With the help of a friend and with the channels in vertical position, we lifted the lower solar panel in place, balancing it in one hand while securing it with the bolt hardware with the other. Not an easy task! Eventually we got the four corners attached so we could install the upper panel. For this one, we decided to hinge out the awning, supporting it with a ladder and some blocks so that we could use gravity to our benefit. It was a little bit of a challenge to get in place but much easier to install the bolt hardware. We installed the remaining hardware, then tightened everything down feeling good about that progress.

With daylight fading, I postponed installing the vertical posts until another time, so we lowered the awning to a vertical position until then.

Once ready to install the posts, I evaluated the angle I wished to set the panels at knowing that the ideal angle for Oregon is somewhere around 35 degrees. I had 45 degree angles cut in the 2"x2" aluminum tube posts so with the help of my reciprocating saw and angle grinder, I modified the angle to make it closer to 35 degrees. In hindsight, I should have just had them cut it to that measurement. Anyway...

A friend suggested two bolts per attachment to the rail for better stability so I drilled two holes in line on the angled end of the tube and then one for the bottom bolt attachment. I decided to use an L bracket screwed to a 12"x12"x3" concrete block as the base for each post.

With all of the holes drilled in each section of aluminum tube, I lined up each post with the mounting spot on the rail and made marks for holes. Then I drilled the holes and installed the bolts, washers and nuts to make the rail and base connections.

All that was left then was to make the wiring connections. Part of me wishes I had left the wire running through the wall of my house because it was difficult to feed it back through. Of course cold weather and hands didn't help either! Eventually I succeeded, capped the ends and waited until dark to make the panel lead and charge controller connections. For those of you who don't know, solar panels collect sunlight and make energy even when they aren't plugged in so you have to be careful with the ends which is why I waited until dark.

I am excited to have my solar system back together again! More photos on flickr too :)

The design for the new frame is similar to the old one, trading 2x2 cedar supports for 1 1/2" x 1 1/2" and 1 1/2" x 2 1/2" aluminum C channel. I drilled holes in the bottom of each section of channel to align with the holes in the solar panel frames. In more typical residential solar installs, special rails and hardware clamp the panels in place but I was looking for a lower profile design since I had just under 2" depth to play with. I placed the narrower channels in the middle and wider ones on the outside since they would also accommodate the vertical support posts.

With all of the holes drilled, I went to work attaching them with bolts, nuts, washers and lock washers to the piece of 2" unistrut tube that was already attached to my house via welded on hinges, a piece of angle iron and all-thread. Of course I had to measure to make sure their placement would line up with the spacing of the holes in the solar panel frames. I also didn't tighten things down completely since it's a good idea to wait until everything is in place just in case a little extra wiggle room is necessary.

With the help of a friend and with the channels in vertical position, we lifted the lower solar panel in place, balancing it in one hand while securing it with the bolt hardware with the other. Not an easy task! Eventually we got the four corners attached so we could install the upper panel. For this one, we decided to hinge out the awning, supporting it with a ladder and some blocks so that we could use gravity to our benefit. It was a little bit of a challenge to get in place but much easier to install the bolt hardware. We installed the remaining hardware, then tightened everything down feeling good about that progress.

With daylight fading, I postponed installing the vertical posts until another time, so we lowered the awning to a vertical position until then.

Once ready to install the posts, I evaluated the angle I wished to set the panels at knowing that the ideal angle for Oregon is somewhere around 35 degrees. I had 45 degree angles cut in the 2"x2" aluminum tube posts so with the help of my reciprocating saw and angle grinder, I modified the angle to make it closer to 35 degrees. In hindsight, I should have just had them cut it to that measurement. Anyway...

A friend suggested two bolts per attachment to the rail for better stability so I drilled two holes in line on the angled end of the tube and then one for the bottom bolt attachment. I decided to use an L bracket screwed to a 12"x12"x3" concrete block as the base for each post.

With all of the holes drilled in each section of aluminum tube, I lined up each post with the mounting spot on the rail and made marks for holes. Then I drilled the holes and installed the bolts, washers and nuts to make the rail and base connections.

All that was left then was to make the wiring connections. Part of me wishes I had left the wire running through the wall of my house because it was difficult to feed it back through. Of course cold weather and hands didn't help either! Eventually I succeeded, capped the ends and waited until dark to make the panel lead and charge controller connections. For those of you who don't know, solar panels collect sunlight and make energy even when they aren't plugged in so you have to be careful with the ends which is why I waited until dark.

I am excited to have my solar system back together again! More photos on flickr too :)