(cue Snap...)

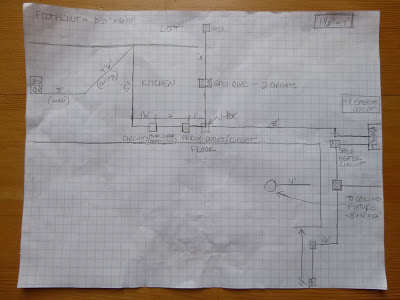

Well, it's been about a month since we made the final connections to connect my house electrical to the sub-panel in the shed. It was quite the process, trying to figure out what components of the boat and RV worlds to use and how they can (and need to from what I found) work together. Since I built my house to electrical code and don't currently have any propane appliances, I decided to go with a Camco 50 amp extension cord with an RV style plug on one end and a marine style plug on the other end. (Note: You may be able to make your own cord for less money, but after pricing out 6 gauge wire and the different style ends (about $100 just for the marine style end), I decided a manufactured cord was best for me at around $200.)

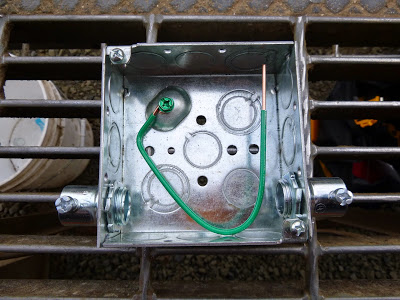

This cord has four 6 gauge conductors (1 ground, 1 neutral and 2 hot for 120/240V service) which is sufficient for my electrical loads. The RV end has a PowerGrip handle which makes unplugging much easier from the standard 50 amp receptacle we installed on the outdoor shed. The marine style end has a twist-lock design with a threaded locking ring for a secure, waterproof connection to the Marinco power inlet I purchased. It came with a rear safety enclosure for use within a floor or wall, with 6 gauge conductors connecting directly to the panel but since I chose a surface mounted design, we had to find a different way to connect it to conduit through the floor and up the wall. Luckily, with the generous help of a friend, we found a weatherproof electrical box and extension ring with gaskets that were compatible with both the power inlet and the conduit.

Once we had all of the pieces necessary, we measured, marked and drilled yet another hole in the floor. Somehow I was about 3/8" off from missing the rim joist (I still can't figure out why other than having to remember shell construction from a year ago) so we had to cut that out a little. Oh ya, and we had to jack up my house again since the hole we were trying to drill was in the same place as a CMU foundation block (of course). I worked at breaking the block in half so it could support my house and still leave space for the hole and cord to plug in while my friend assembled the weatherproof box pieces and inlet. Once that was complete, we connected the conduit to the box and electrical panel via set-screw connectors. Then we pulled wire, made the connections, secured everything in place and plugged in the extension cord.

Finally, we flipped the breaker in the shed sub-panel, started flipping breakers on in my house and everything was a success! It's been really great to have my own fridge running to keep things cold in the summer (though I may go back to outdoor refrigeration in the winter), warm water to do my dishes, ease of plugging in kitchen appliances and my fan, and really awesome to flip on my light switch to this!